Density Article part 4 - Single serve coffee on the Mahlkönig EK43

BY CLAY BUSH

This article is the fourth in a series that introduces roast density as an integral part of the coffee roasting and brewing process. The first article “The Density article part 1 - Green and Roasted Bean”, introduces density measurements. “The Density Article part 2 – Particle and Puck Density” is an overview of new concepts like Particle and Puck Density, explaining what they are and how they are used.

The third, “The Density article part 3 – How to check for Dull grinder burrs” explains the linear relationship between puck density and grind setting changes, and how this simple process can be used to determine dull burrs, grind windows, and burr calibration.

These articles are written in a deliberate sequence to build on a theme. A theme we hope presents a compelling argument for roast density to be included as a standard of measurement in the coffee industry.

For this to be the case, an understanding of roast density needs to be built and viewed as a collective study. These principles can only be found here, and prior knowledge of these articles is needed before you can understand this current article.

By reading these articles you will find ways to understand your coffee and your grinder more and make sure that it is all in working order before moving forward to testing a coffee and understanding puck dynamics. For instance, if your blades are not aligned, dull, or are outside of their “grind window”, how can you trust your results? There is certainly no point in doing any testing. However, by using roast density and puck density we can build a new measurement system. A system that can go all the way from green bean to extraction.

In many ways, it was a school that we ourselves had to pass through whilst developing our new Bush and Bush coffee systems calibration tool. The coffee industry has many standards that are not so….. well….. “Standard”. A study of puck density will very quickly highlight these shortcomings. So before going forward and performing testing it is vitally important that we test our testing process. Because if your methods are inconsistent from the outset, then all of the following tests will be inconsistent.

Perhaps the biggest shortfall in our industry is the practice of single-serve coffee. You will have to abandon this practice if you wish for consistent grinding practices. There is no doubt this view will come up against some strong opposition, so we have written this article to highlight this shortcoming using the physics of puck density.

Most think that putting beans in a grinder will herald a uniform, repeatable, particle distribution. Nothing could be further from the truth. An accurate grinding process is a cornerstone to understanding the shifting sands of puck dynamics. If you create inconsistent grinding methods you will get inconsistent results. For many, the only reason why they haven’t seen these inconsistencies in their process is because they haven’t had a yardstick to measure them.

Never was this more obvious to me than when we first started “officially” testing puck density back in 2015. It became evident on the first day that grinding inconsistencies are paramount in the specialty industry. Inconsistencies were introduced when baristas started forgoing the grinding process in the search for fresh, grind on-demand coffee.

In upcoming articles, we will focus on what we believe is the last frontier of coffee. The point where roast density meets burr geometry. But first, we must go back a step and focus on the grinding process.

We dedicated 3 months to grinding practice before we started testing, and the best way to highlight inconsistencies in the grind is through single-serve coffee.

A thorough dissection of this process will highlight its faults, help you to understand your grinder, and by default highlight a correct method.

This article is not a beat down on those who use single-serve coffee. It is unavoidable in some circumstances. Moreover, it’s a forum to highlight inconsistencies that can happen when grinding. The nature of single-serve allows us to test many different methods and ideologies that a full hopper can’t. Any faults in the method of grinding must be known so we can create an accurate process before moving onto burr testing.

I am the first to acknowledge that the grinding principles outlined in this article may be impractical when faced with the real-life pressures of a coffee bar. But we must be as accurate as possible during QC testing and then later look for ways to implement these findings into the coffee bar process or equipment design.

Coffee grinding is one part roast density, one part grinder capability, and one part burr geometry. To get the whole picture you must understand your coffee, your grinder, and what happens when they meet. We wrote an article a few years back called “Know your grinder”. To give this article some context and also build upon a theme, we have quoted practices used in this article. If you have not read this article it can help to flesh out grinder practices.

There is probably no greater grinder used for single-serve coffee than the Mahlkonig Ek43. So for this article, it seemed obvious to use this as our test grinder. The EK has a few traits that aren’t seen in other grinders, its dial face with numbers makes for great markers and ease of understanding. So it’s great to highlight as much information about puck density in one article. So let's get into it.

Again just to note before performing these experiments we:

Understood the grinders duty cycle.

Checked its cutters are sharp.

Checked alignment.

Understood the burr geometry window of the cutters we are using.

Note; Grinder testing is only of importance after these steps have been achieved. Only then can we grind coffee and expect accurate results. It’s important to note at this point that the standard EK burrs are not consistent in the realm of espresso. To understand why please read the “Density article part 3 – How to check for Dull grinder burrs”. This article addresses the burr window of the EK.

In short, we explained in this article that the standard Mahlkonig cutters do not hold a consistent grind window in the espresso range. Under normal circumstances, I wouldn’t continue testing. Instead, I would search for burrs that keep a consistent 3 point check through the grind window for the espresso grind range. Experience in puck density highlights the fact that inaccuracies always occur when a three-point check can’t be achieved. However, for the sake of the article we shall continue, But please keep in mind that in our opinion these burrs are not designed for espresso.

The last thing we need to ensure prior to any testing is coffee selection. It should go without saying, when testing grinders, always use a single-origin coffee, with consistent screen sizes, never use a blend the inconsistent densities of several origins will affect your puck density. (more on this in the bur geometry article.) For the sake of this article we are using a first crack espresso roast, single-origin coffee, which extracts above 20% solubles yield, with a cupping score of 86. We used this coffee to show some form of consistency, without being unrealistic. A 90 plus, you would hope has a better grading and will therefore likely herald even more consistencies, but I’m going to assume that most coffee folks don’t extract 90+ through an Ek grinder for espresso. So, an 86 is probably more relevant to the general coffee bar espresso.

So now with our new understanding of puck density, together with burrs tested for cutting prime, and an understanding of the burr geometry window, we can finally proceed with the testing.

Hopper weight.

In our article getting to know your grinder, we looked at how decreasing hopper bean load affects the weight on the cutters. It highlights how both the hopper shape and bean mass determines the weight transferred to the burrs. This declining hopper mass simultaneously lessens the weight on the blades, which in turn can affect the quality of the cut. So the first, and most logical question when debating the single-serve validity is, does the transfer weight of bean load pressure affect the consistency of puck density? Ie the quality of the cut.

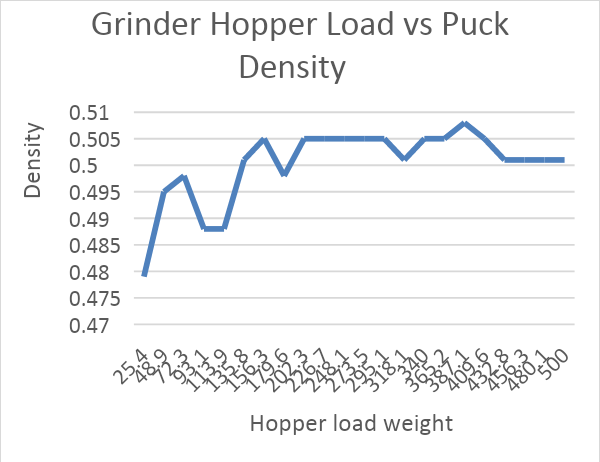

The easiest way to do this is to leave the grinder on a set grind number and measure the puck density of each shot, these densities can then be compared to the diminishing bean volume in the hopper. If the diminishing hopper weight has no effect on puck density, then because we haven’t changed the grind, our puck densities should remain consistent regardless of the decreasing bean volume in the hopper. The densities in the following graph are at an espresso grind setting, and because outside of the Burr geometry window contain some “static” from inconsistent grinding. For an understanding of how we measure hopper load vs burr weight. See our article getting to know your grinder here

Graph results:

Graph 3. The top graph is grinder hopper load and its corresponding weight on the burrs. The bottom graph is the same decreasing burr weight and its effect on the densities. We’re looking for a trend in these graphs and it should be clear. At 200 grams both samples begin to fall away.

It can easily be seen that as the bean weight on the burrs decreases, the puck density also decreases. They follow a general trend of declining hopper weight and declining puck densities. Baristas with a keen eye will notice this effect on their house grinder. This fall off, usually at around 150 grams of beans, happens in most grinders we have tested. As clearly seen in the example above, the density is lowering even though the grind setting was not changed. This means that your coffee will drift courser as your amount of beans in the hopper decreases. This should be enough to highlight that hopper weight affects puck density. That is, as the weight on the burrs lessons from a declining bean mass in the hopper, your grind will slowly drift coarser.

Why is this effect happening? The burrs in our example we’re kept at the same distance (grind setting) so the puck density should not change. (i.e. the grind should not change. ) However, the density is lessening. The only logical argument is that the bean weight forces the beans through the cutters at a metered rate, allowing the burr geometry to perform accurately. As bean weight diminishes so does this pressure on the coffee passing through the burrs. This lack of pressure allows the grinds to move through the burrs at whatever angle they please, disabling the effect of the cutter geometry. Most likely the long “sausage shape” grounds are sliding through longways as opposed to being cut in half with the bean mass pressure. The added weight of a full hopper will prevent grounds from rearranging themselves as they pass through the burr geometry. Thereby allowing the burr geometry to act as the engineer implied.

If this “sausage principle” is correct, it should continue through to our single-serve trials.

(P.S For those who think the above results are from burrs heating up and therefore expanding to make the grounds coarser. This is not the case. At the conclusion of the test, we filled the hopper again and took more samples. The density immediately increased. So cutter heat being transferred to the coffee is not a factor in this test. Probably in any test to be honest. )

“Popcorning coffee”

The term “popcorning” is used to describe a single-serve process. Its explained as such because when coffee beans are dropped on spinning burrs they bounce back, because of the lack of bean hopper pressure to force them through.

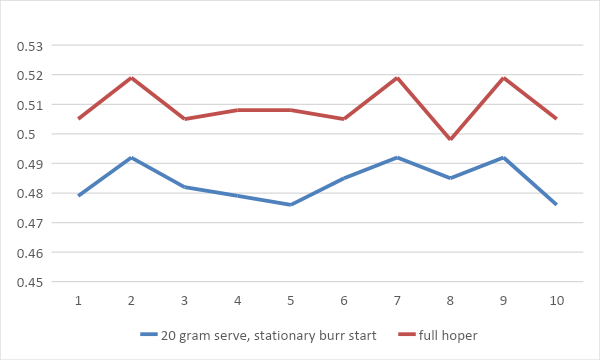

The next step is to test this as a single-serve process against a full hopper. 10 samples of both full hopper and popcorning were taken, whilst keeping the same grind setting. The results are charted below.

Graph 4. 10 coffee samples of Single Serve Coffee dropped on spinning burrs (green) and 10 samples from a Full Hopper. (red) All samples generated are recorded as Puck density measurements. This experiment further supports our Hopper load experiment. It can be seen here that coffee dropped on spinning burrs will create a much more uneven puck density.

By now we can start to see that single-serve coffee can have an effect on the consistency of Puck Density. But let’s not stop there. These results highlight possible further ramifications of single-serve coffee. But before we move forward with more testing, we need to find a more consistent way to grind single-serve coffee more accurately. Is it Possible?

Stationary Burrs Vs Moving Burrs

I’m going to cut to the chase here. There was a lot of boring and repetitive testing which we performed to try and fix the popcorning problem including spraying water on the beans prior to grinding, in case static was causing fines to stick to the inside of the bag shaker, which may affect density readings. None of these methods turned any beneficial results. Duplicating the results here will make for a longer article for no gain so the results were omitted.

There was only one technique worth note. Stationary burr load! In this experiment, we put the 20gram sample in the grinder before turning it on. The idea behind this is to limit the popcorning effect of beans hitting spinning cutters. The results are below.

Graph 5. Single-serve coffee with a stationary burr compared to a full hopper. In this method, we poured a sample into the grinder then started the burrs after the beans had settled. Over several trials, this proved to be the most consistent way to grind single-serve coffee.

We performed this test on 3 separate occasions, on three different bean samples. The above graph is the best result of all stationary burr load tests that we performed. Although this series shows the single-serve stationary burr to be comparable in terms of consistency, It was not the case across all occasions. In the other two series, the full hopper was still more consistent. Even so, the stationary burr technique proved to be the most consistent single-serve technique. So, it was used for the rest of the testing. So if you take nothing more from this article, take this. Don’t drop your coffee onto spinning burrs. Put your coffee in and then start the grinder. And no it won’t break your Ek to grind this way.

Single-serve = lower puck density.

Even though the results of the preceding graph show that single-serve coffee, (on stationary burrs) on a good day can be comparable in regards to grind consistency. There is a greater cost. You will notice that on the same grind setting that the stationary burr, single-serve grinding method, grinds at a consistently lower density even though the grind setting is the same. From our discussions above we know that a drop-in puck density comes from grinding coffee coarser.

When we grind coffee coarser it creates larger particles that have more air space surrounding them, This more airspace in the puck, lowers puck density, and increases flow rate. However, in this case, we haven’t changed the grind setting. What this means, is that grinding single-serve coffee creates more “boulders” in comparison to full hopper grinding. Even with a stationary burr load, the “sausage effect” is still happening.

The comparison you see above is no comparison at all. The single-serve coffee is out by “a few clicks” it's not an espresso grind setting at all. Because we have chosen a single-serve over a full hopper, we must now change the grind, making it finer to reduce the space between the boulders caused by single-serve grinding. And therefore, increase the flow time, and simultaneously increase the puck density. So let’s dial in the grinder to a comparable flow rate using the single-serve grinding and pull another sequence of shots, and plot on another graph.

Graph 6. Both full hopper and single-serve stationary Burr samples dialed into the same Puck density. Because the precursor of puck density is matched, the flow rates out are similar. 19.3 grams in, 49ml out in 26-28 seconds. The top graph shows 10 samples of the full hopper and ten samples of popcorn/single serve. The bottom graph is the corresponding grind position on the dial. Red is full hopper, blue is single serve.

Once the grinder was dialled in to run a full hopper and single-serve to create the same puck density and flow rate, we checked their TDS. Unsurprisingly the Single-serve coffee extracted higher at a 21.5% yield, whilst the full hopper extracted at 20.5% yield. On blind tasting, 100% of tasters agreed that the full hopper coffee was smoother, sweeter, and more rounded. The single-serve coffee was sharp, slightly bitter with less sweetness.

On close inspection, this higher soluble yield came at a cost. The cost is more fines. Remember whilst their puck density is the same, the single-serve coffee needed to be milled finer to get the same puck density result. This finer grind setting is to compensate for the boulders formed through the popcorn effect and improper use of the burr geometry.

I once read an article where an Instagram blogger stated that popcorning coffee can be fixed by simply grinding finer. And by looking at the above results it would certainly appear so. if you use run speed as your metric. But that is not the case. The single-serve had to grind at a finer setting (grind setting 2), than the filled hopper sample. (Grind setting 2.5) So whilst their puck densities are the same, the particle distribution of these densities is not.

When grinding the single-serve sample finer the distance between the blades is smaller resulting in smaller particle size. Because we have ground finer, the particles should be finer, and the puck densities should have raised. (Smaller particles equals a higher puck density.) Whilst the flow time is the same the puck density has not raised in comparison to the full hopper sample.

Here we have to read between the lines. From our Density article number 3, we know that a change in grind will change particle size, which results in a consistent change in density. The disparity of the particle distribution that has resulted from the popcorn effect has not been fixed. The boulders have simply been made into smaller boulders.

This means that the single-serve sample must by way of a physics measurement, STILL HAVE BOULDERS in the sample. Grinding finer has not fixed the popcorning effect.

I understand this may be overwhelming and hard to understand. But after some time studying puck density, these results start to become obvious.

Single-serve coffee in comparison to a filled hopper will cause popcorning, inefficient use of burr geometry, an uneven particle distribution, and therefore, a need for compensation. The only compensation can be in the change of grind to slow the flow rate.

However, It will not return it to its original full hopper distribution. It also bears mentioning that the grind window of the EK is not linear in the range of espresso grind setting. This brings us to our final problem.

Burr Geometry window.

Remember our burr geometry window for standard Mahlkonig cutters from our last article? Its minimal acceptability for consistent milling is setting number 4 . (12 o’clock on the dial) That means any coffee ground finer than this grind setting will most likely contain some form of inconsistent grinding, regardless of the hopper being filled or not. Both the full hopper and single-serve samples are within this inconsistent range which means you have fallen outside the cutter functioning window of consistent grinding.

To give you some context we ground some samples at the grind setting number 4 to highlight how much inconsistency is in the espresso samples. See below.

Graph 7. 10 samples ground at #4 and added to the graph for comparisons. The espresso samples provide much more grinding inconsistency in the range of espresso. To put it in context, the single-serve, and full hopper variance between samples, is the equivalent of about a notch invariance under the old school system, whereas the variance in puck density of the samples generated at grind setting #4, is about a “quarter of a notch in the old system”. This higher consistency shows that the burr geometry is more consistent in the window of the filter. Making the Ek with standard burr more suited to filter grinding.

In Closing

In this article, we used the standard Mahlkonig cutters for this Testing. We tested with these burrs because they are the most widely used burrs on the market for espresso. In the defense of Mahlkonig, their Turkish burr cutters ARE consistent in the range of espresso. Albeit with a different puck density and therefore resulting flavor. The Turkish burrs also hold a much greater “grind window” for espresso than any other EK after-market burr tested. This screams to me that there is a deliberate design to their burr geometry, and they have divided the entire grinding window into two burr sets.

It should also be of note that there are also other burrs on the market that do hold consistent grinding in the range of espresso. Including both sets of Gorilla gear cutters. (Turkish and filter) However, this consistent grinding is only in the presence of a full hopper.

As stated at the beginning of the article, this is not a beat down on single-serve coffee. It is at times unavoidable. The error is in the assumption that single-serve coffee has no detrimental effect on particle distribution. Once we acknowledge that single-serve grinding is an inconsistent way to grind coffee. We can then devise new ways to feed cutter weight and alleviate this problem.

Manufacturers are constantly making changes to grinders to address these issues. A few of note include hopper feed rate, hopper neck diameter, burr feed angle, and pre-feeders (I call them worms). All designed to assist consistent use of burr geometry. It doesn’t make sense to not use them.

We will talk more about these in future editorials. Until then, Happy Grinding

Cheers ,

Bush & Bush Coffee Systems