Little Red update.

A considerable time ago, my brother Jake and I embarked on restoring the small 400-gram roaster at Pillar Coffee. The roaster's heat transfer was docile and unsuitable for our current roasting method. So, we set out to adapt the roaster to more modern roasting techniques. We hoped that between myself and Jake, we could pool both our skills, mine as a roaster and Jake as a process engineer, to create a proto-type roaster. To see the first part of this journey, see the article, a discussion between a coffee roaster and a process engineer

The basis of the roaster was to test theories developed over a six-year study into green and roasted bean density.

Creating the densitypress changed many of my beliefs in coffee roasting and raised many more questions. So, our prototype roaster was to become the vehicle to test and expand this inquiry.

To do this retrofit justice, we had to not only retro the roaster to answer pressing questions but also fit the roaster with new abilities for new, unknown avenues. The Roaster needed to be capable of adjusting all the dynamics of heat transfer independently, essentially building a machine that was capable of more than would ever be required to find what was needed. Even to this day, after roasting on Little Red for over a year, we are still adding new probes, creating unique measurements and developing algorithms to measure heat transfer.

An essential part of this restoration was to make a roaster that could provide data on the heat transfer beans experience during roasting. Extensive instrumentation would be required for this, with the ability to be expanded as more questions arise. Then, the operator can correlate this data with the results in the cupping bowl.

Furthermore, this whole process must become a vehicle for determining predictable outcomes, so some automation would be required for repeatability purposes.

Data removes the "gut feel" that we, as roasters, are forced to adopt because of a lack of systematic data.

Density and associated measurements are the key to this endeavour.

So, with that in mind,

Here is the scope of work completed on the roaster thus far.

Overview

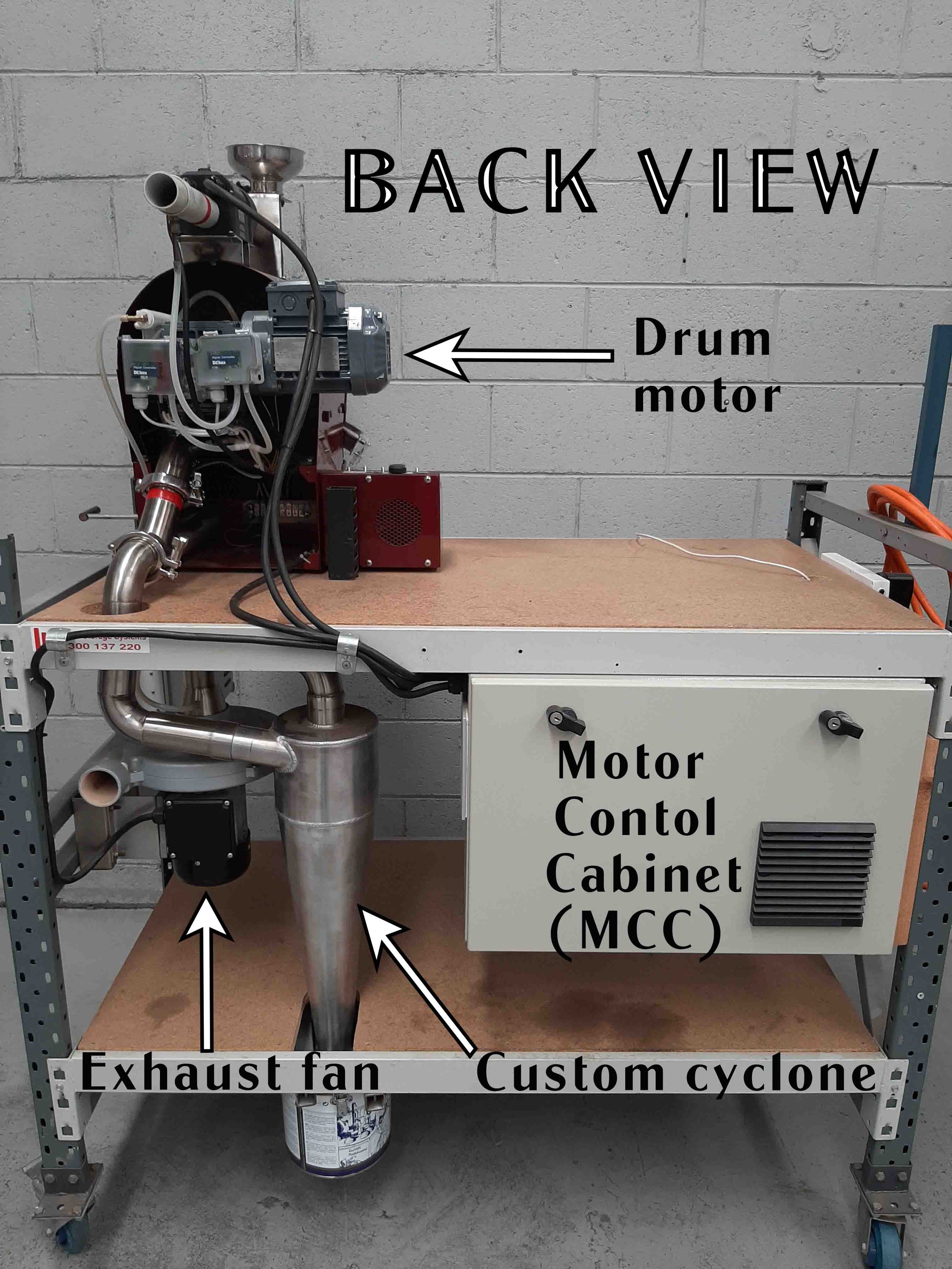

A new Drum Motor was installed with a Variable Voltage Variable Frequency (VVVF) Drive, motor control cabinet (MCC), and an instrument panel, displaying all outputs through Artisan Roasting “Software.

A cyclone was designed and installed,

(Front View.)

(Back View, Custom Cyclone was engineered, Drum motor and Motor control Cabinet installed)

TWO independent fans.

Inlet fan.

The inlet fan is part of the inlet burner. However, the “burner” is electrical, and the airflow is not required as a combustion fuel source for the burner like a traditional gas burner. This way, we can make the inlet heat and airflow independent.

Exhaust fan

The exhaust fan is on the outlet of the cyclone. This fan is also variable. It provides a draw to clear the drum of smoke and chaff. Its dual function is to cool the beans at the end of the roast.

Why have two fans?

Whilst every roaster has an internal pressure that it functions at, generally, it is not manipulatable. The fan's purpose in larger-scale roasters is to facilitate combustion and, in the case of indirect roasters, facilitate heat transfer. So, the pressure results from the transfer and is generally not manipulatable.

Our roaster is fully electric, so a traditional fuel mix is unnecessary. This allows us to separate the fan and heat to manipulate pressure and flow independently of the combustion effects determined by a conventional gas burner.

(Independent fans were installed for manipulation of pressure and flow independent of heat sources)

Two independent sources of heat transfer Convective and Conductive

Convective

Convective air is delivered through an electric blower on the top of the roaster.

Conductive

The conductive heat source comes from the original electric IR elements radiating onto the drum surface. A VVVF Drive now supplies the power to these elements making them fully adjustable.

This way, we can supply varying heat sources on the drum skin and the air. Both heat sources are independent and variable.

The theory is to roast the coffee through conductive heat on the drum skin to maintain and match the heat of the inlet. Both heat sources can provide up to 500 degrees of heat independent of one another. Allowing us to roast with either heat source exclusively or in unison.

Why?

Whilst all roasters have a combination of convection (air) and conductive (direct), these individual heat transfers are usually combined and a result of one heat transfer source; in our prototype roaster, separating the two from one another was essential. This way, we can apply heat on the skin independently of the convective heat passing through the drum. It will allow for a more finely tuned heat transfer.

(photo of inlet convective heat and conductive radiant heat source }

Temperature probe installations.

Little Red has seven temperature probes.

1. Bean probe.

In our roaster, whilst roasting, the bean pile moves clockwise up the drum's wall, then falls through the air and back down to the base of the drum. The bean probe is positioned in the centre of this circulating pattern. For a more in-depth understanding of the bean probe placement in the context of drum/skin speed. See our YouTube video here.

2. Inlet Probe

The inlet probe is put after the inlet burner and before the drum entry to measure the temperature entering the drum.

3. Drum probe x2

Conventional Production roasters don't have drum probes.

Depending upon the drum and internal paddle construction, the drum probe is installed in either front or back faceplate.

Our larger production roasters only have one drum probe (in the front face plate). In Little Red, we have put two probes. The first is in the back plate and sits at the same height, directly opposite the bean probe. In a drum roaster's regular rotation and paddle system, beans get pushed to the front and then moved up the drum skin and thrown to the back of the drum. This moving forward and backward in the drum is to circulate the beans in the airstream and deliver them to the front for exit when the door is opened. So, in the back of the drum, opposite the bean probe, is an area free of beans, so the air temp can be measured.

The other drum probe location is in the front faceplate, opposite the bean pile. Another space, void of beans, to measure air temperature.

Why?

The drum probe was a probe that Jake suggested.

Regardless of the location, the role of the drum probe is to measure air temperature as close to the bean pile as possible without actually measuring the beans themselves. In this way, we can see heat radiating off the bean pile and also being applied to the bean pile in real-time.

(Inlet probe, bean probe, and front drum probe. The drum probe is also placed in the back of the drum. Both probes are designed to be in the airspace surrounding the bean pile. )

4. Exhaust probe, placed where the air exits the drum.

(Exaust probe at exit of Drum, and rear drum probe located in air pocket surrounding the bean pile

5. Conduction Probe

A conduction probe is placed outside the drum where the elements radiate onto the drum skin. It measures the temperature of the heat applied to the drum via the radiant elements.

(The Conductive probe is to measure the heat that is being applied to the surface of the drum by the conductive elements)

6. Skin temp probe.

The skin temp probe is an Infrared red probe placed on the outside of the roaster and aimed at the drum skin. It gives us an idea of the drum skin temperature and, therefore, an indication of the conductive heat applied to the beans. .

(Infrared Temp probe pointing at outside of the drum, at the bean pile collection point)

Humidity sensor

A Humidity sensor was installed in the drum exit to measure humidity changes during the roast.

Why?

To measure the changes of moisture in the drum throughout the roast.

Air volume

This measurement was added to check air velocity and resulting roast defects. And also to see relationships between air velocity and heat transfer.

Differential Air Pressure.

We measure the difference in air pressure between the Inlet and Exhaust to determine the pressure in the drum. Adjusting the two fans independently allows us to change the Air flow rate (volume) through the drum and the pressure in the drum independently, and as such, both have to be recorded.

Skin speed. (as opposed to RPM)

2. VVVF Drive on the Drum.

A Variable Voltage Variable Frequency Drive was placed on the drum. This is represented as skin speed, not RPM.

RPM is not a relevant measurement in roasters as revolutions are meaningless without reference to drum circumference.

Various Algorithms designed on Artisan software.

Despite the physical changes made to the roaster, various algorithms have also been developed from these probes to understand the evolution of heat transfer throughout the roasting process. These are “virtual” traces on the software using algorithms from combinations of instruments.

But are all these modifications essential?

Whilst only a 400-gram roaster, the changes made to Little Red are thorough and complex for a roster his size.

The Advantage for Pillar Coffee is to have a roaster that can be used for our high-end competition-style roasting.

However, these modifications for Bush and Bush Coffee Systems have different purposes. They help us understand heat transfer and its effects on bean density.

To do this, we must be able to test and isolate specific elements of the heat transfer process. It's something hard to do on commercial roasters.

For example, we can devise a simple experiment to illustrate the effect of airflow on heat.

First, roast a control profile with set parameters using a pull-up profile. Then, roast a second experimental profile, making one change for a simple comparison.

The second profile must

a.) Maintain the same inlet temperature with the inlet burner.

b.) Maintain the skin temperature as controlled with a separate conductive heat source. Then,

c.) Increase airflow through the drum by manipulating the inlet and external fans. whilst

d.) Simultaneously maintain the internal drum pressure

This way, we have duplicated the same drum environment with the same beans but increased airflow.

After roasting, we cup and then check the resulting density changes using the density press and associated software.

Now we have the curve, the bean's physical changes and the resulting flavour profile.

So what have we learnt so far?

First and foremost, the green bean can receive far greater heat manipulation than production roasters can apply.

Two coffees that may taste the same in the cup may or may not have the same physical attributes. Ie just because you think it’s the same, doesn’t mean it’s the same.

Also, it is impossible to separate your roaster's heat transfer from the results in the cup. What's more, the effect your roaster has on your final cup is primarily a result of the heat signature of your roaster and not the bean itself.

For instance, did you know that 1st crack temperature can be manipulated by at least 40 degrees? I certainly didn't until I saw it with my own eyes. This is unknown because our production roasters don’t have the means to manipulate it. But that doesn’t mean the bean can't do it.

With every discovery comes a new direction. And there have been many. There are so many that it's not feasible to illustrate those principles here.

Not to mention that some of the revelations will be met with opposition from the roasting community. It is a welcome debate unless those discussions are egotistic and not physics-backed.

However, one principle is a constant that ironically draws little attention from the larger roasting community.

Roasting Coffee "appears" to be increasingly about the controlled migration of moisture released from the bean. This migration of moisture is the result of applied heat. And it is a reflection of the inner momentum of the bean. This line of question now occupies most of our time.

Investigations are thorough and methodical.

We roast the coffee and record the outputs through software, cup the coffee, and then measure the coffee to see the physical changes the bean undertook through the changes in roasting.

This is the density process.

For this industry to make meaningful advances, we must be accountable and move away from the gut feeling our industry is known for.

For us at Pillar and Bush and Bush Coffee Systems, Little Red and the density press are the first steps in this process.

Much more to come.